Home Video Overlay Motion Control Turbine Turning Tools Corporate How to find us Support Search Register

|

Home Video Overlay Motion Control Turbine Turning Tools Corporate How to find us Support Search Register

|

Razor Blade Geometry Measuring System.

THE BRIEF:

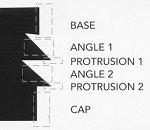

A leading manufacturer of shaving blades approached us to develop a non-contact method of measuring the angle and protrusion of twin and single blades encased in a plastic cassette. The angle of the blade is very important in producing an effective cutting action of the hair base and is about 20 degrees. The protrusion must be large enough to cut the hair but short enough to avoid penetrating the skin.

Razor blade

Razor blade

There are a variety of ways of projecting a line onto a surface. The instinctive solution would be to use a "laser diode line projector" (this consists of a laser and rod lens producing a fan of light). However, the specular and granular nature of the materials in the cassette produced "hot spots" caused by direct reflections of the laser beam into the viewing device. Interference effects, due to the coherent laser light, exacerbated this problem.

The solution was to cast a shadow onto the cassette. This way, the specular surface made no difference since there was no light at the points of interest.

Razor

blade

Razor

blade

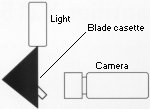

A camera placed at right angles to the shadow generator (shown on left below), with the cassette placed at 45º between the two produces an image of the profile (shown on right below)

Shadow generator

Shadow generator |

Profile image

Profile image |

The IQ150 digitises six strategic areas to calculate:

|

Digitised image

Digitised image |

The IQ150 produces a repeatability of 1 degree on angle measurement and 12 microns for protrusion, ten times greater than the required specification.

Copyright © 2002 Cortex Controllers Ltd. Cambridge, UK. All Rights Reserved.