Home Video Overlay Motion Control Turbine Turning Tools Corporate How to find us Support Search Register

|

Home Video Overlay Motion Control Turbine Turning Tools Corporate How to find us Support Search Register

|

IQ150 WELDCHECK

A leading UK manufacturer of automobiles required to inspect rear axle welds for weld penetration, throat and leg length.

Special software was easily written for the IQ150. The operator takes the polished and etched weld cross section and views the image under an Olympus zoom microscope fitted with the unique Cortex encoder. The imaged is zoomed to fill the screen. The operator can then move, with the track ball or keys, the cursors into their specified places.

An RGB Version of this product is available. Quote Product code S278

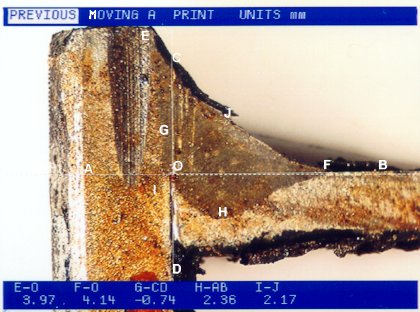

Screen shot of sectioned weld

Points A and B are moved so that a horizontal line is best fitted along the horizontal edge. Points C and D are then moved to best fit a line on the vertical edge. The IQ automatically works out the intersection point called O.

Point E is moved to where the weld meets the vertical edge and Point F to where the weld meets the horizontal edge.

Similarly point G is the deepest penetration of the weld vertically and H horizontally.

Points I and J are where the weld begins and ends at a line through 45 degrees of O. The IQ150 automatically ensures that the operator keeps to the mid angle.

All measurements are automatically computed and displayed on the screen so that:

E-O and FO are leg lengths

G-CD and H - AB is weld penetration

I to J is weld throat

The system was so successful that five of their rear axle suppliers have purchased the system.

Copyright © 2002 Cortex Controllers Ltd. Cambridge, UK. All Rights Reserved.